Steel: the good, the bad, and how to fix it

30/05/2023

Steel is used in nearly every industry, including the transportation and machinery sectors where Cargotec operates. What makes it such a popular material, and how is Cargotec tackling the challenges that come with it?

The global consumption of steel is close to a whopping 2 billion tonnes annually and is predicted to grow by 30% by 2050 due to population growth and urbanisation. Steel is also used in all Cargotec’s cargo and load handling equipment.

"A typical Cargotec machine is roughly 70 percent steel," says Anna Kawecka, Supplier Sustainability Development Manager at Hiab, part of Cargotec. "The majority is used in the steel structures of the equipment, but the hydraulics and other components we use are also made partly with steel. It’s definitely a key material for us."

Steel is a popular material for many reasons.

"Steel is very durable and strong, which gives it a long life cycle: 75 years on average," says Thomas Hörnfeldt, Vice President Sustainable Business at the steel manufacturer SSAB. "Steel can also be recycled almost indefinitely, and it has a very high recycling rate globally."

The recycling rate of available steel is roughly 90%, but recycled steel only covers approximately 25-30% of all steel produced. This is because, even though the amount of steel available for recycling is expected to grow, it cannot keep up with the increasing consumption. Here we come back to durability: with a 75-year average life cycle, most steel products made by humans are still in use and not available for recycling. This means that iron ore, the raw material for steel, will continue to play a key role in steelmaking.

Tackling emissions from steel

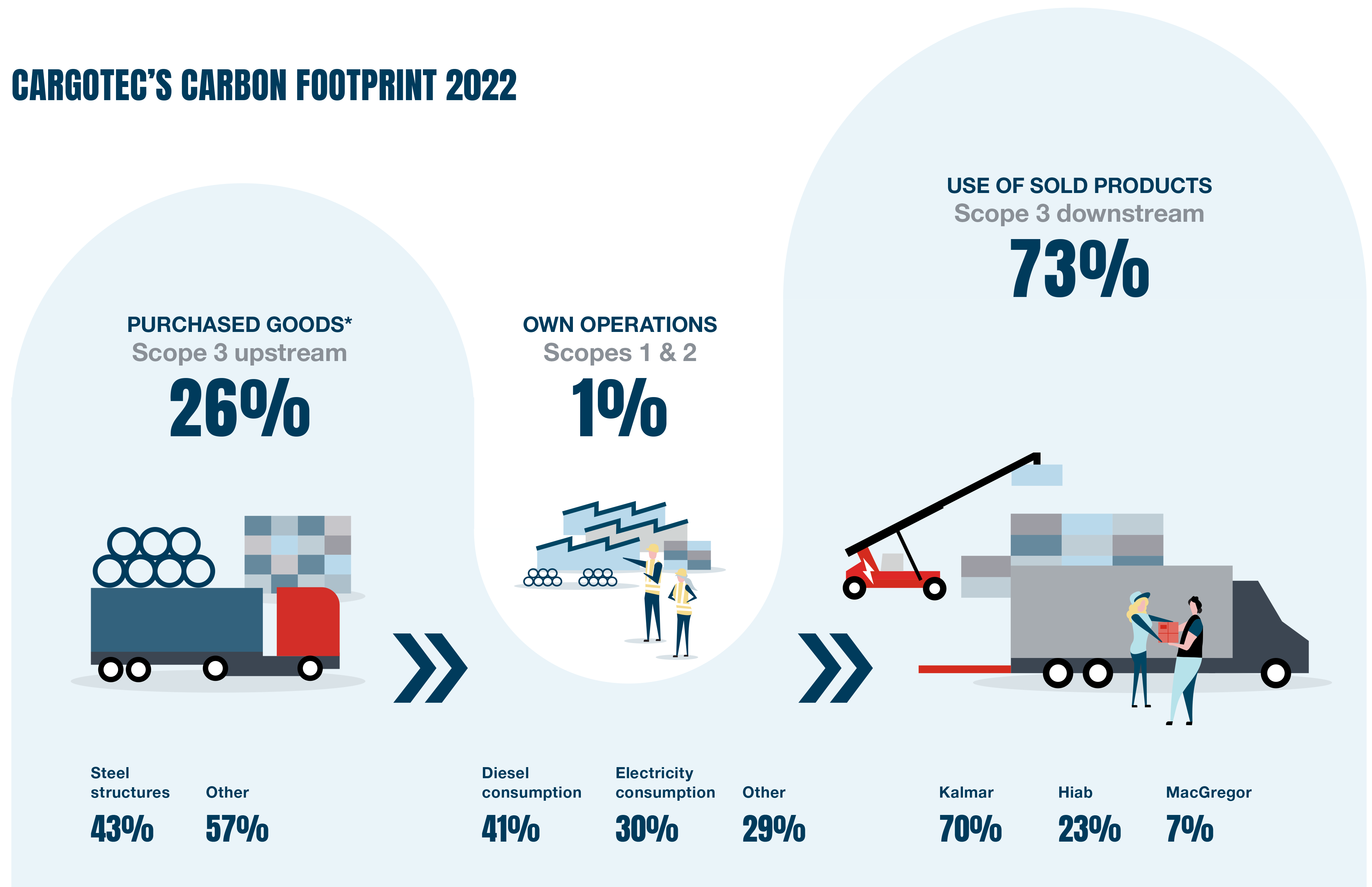

There is a downside to using steel made with iron ore: greenhouse gas emissions. The steel industry accounts for 7-9% of global CO2 emissions, mainly due to the sheer amount of steel produced and using fossil fuels and coal to produce it. In Cargotec’s carbon footprint, steel structures represented 43% of all supply chain emissions in 2022. One way to reduce emissions from steel is to reduce the amount used.

"At Hiab, we have already been able to reduce the weight of some of our cranes by switching to smaller amounts of stronger steel," says Kawecka. "The newer cranes are lighter, which makes it possible for the trucks they're installed on to carry more load. This is ideal for our customers, both from an environmental and financial point of view."

"Kalmar equipment, on the other hand, is made to lift heavy items, such as cargo containers. This means that we need to use heavy materials to keep the machines steady," says Marjolein Koopman, Head of Sourcing Sustainability at Kalmar, part of Cargotec. "In addition to reducing the amount of steel to make the equipment lighter, we focus on finding alternative low-carbon materials. One option could be to use unprocessed, naturally heavy materials, such as stone, instead of steel for the counterweight in some of our equipment."

Similarly, Bromma, part of Kalmar, is using lightweight design and low-carbon materials to reduce the carbon footprint of its famous spreader. All three — Hiab, Kalmar and Bromma — also have plans to re-engineer their existing equipment so that they can be built with new, alternative materials, and to design future equipment in a way that requires less steel.

The future is fossil free

Another way to reduce emissions from steel is to find more sustainable ways to produce it. Cargotec’s ultimate goal is to have early access to 100% fossil-free steel, and we have partnered with SSAB to bring this groundbreaking product to our industry. Hiab introduced the world’s first hooklift made with fossil-free steel in 2022, and Bromma is planning to produce their first spreader prototype made with this steel in 2024.

"SSAB’s Hybrit demonstration plant for fossil-free sponge iron is scheduled to start operations in 2026, and that allows us to start producing fossil-free steel on an industrial scale," says SSAB's Hörnfeldt. "While the wait may seem long, bringing this product to the market is actually happening quite fast, considering how much research and pilots are needed for the new technology. The product is unique, as this has never been done before, and we are quite proud to be moving as fast as we are."

"Fossil-free steel is key in significantly reducing our supply chain emissions," says Kawecka from Hiab. "While we look forward to it being widely available, we will explore other alternatives in the meantime as well. In Hiab’s case, for example, just increasing the amount of recycled steel could reduce supply chain emissions from steel by 50 percent. There are many fixes, and we want to find the best ones."